- Over 1000 skilled professionals across different disciplines work in our factory

- We maintain high quality in machine production, design, and coupling.

- Free support for machine maintenance, operation, and installation.

- All machines used in our factory are of optimum quality

Semi Automatic Fly Ash Brick Making Machine

- All spare parts are from reputable manufacturers

- The frame of the machines and the moulds are subjected to heat treatment to ensure their durability.

- All machines have been certified to be of high quality

- Customers across the world attest to their quality.

The LMT4-40, is a semi-automatic, mini fly ash brick making machine that’s used to produce fly ash bricks from sand and fly ash. It is typically small sized, affordable, and efficient.

Although a conveyor belt has been excluded, there is a robust concrete mixer. This machine aligns with the interests of small scale fly ash brick manufacturers.

- Size: 2050*1660*1900mm

- Production capacity: 2240 (hollow blocks), 4480 (porous blocks), and 6720 (pavement bricks)

- Cycling speed: 35-40 seconds

- Pallet size: 850*550mm

- Power: 5kw

The LMT4-35 is a machine used to manufacture fly ash bricks and as well as other blocks such as paver blocks, concrete blocks, etc.

This mini semi-automatic fly ash brick making machine has a major upgrade over its predecessor (LMT4-40): it has a material hopper which can be fitted with a conveyor belt. Hence, it has higher production capacity and block quality. It is suitable for fly ash brick manufacturers who.are just starting or small scale fly ash brick manufacturers.

- Size: 2050*1660*1900mm

- Production capacity: 2880 (hollow blocks), 5760 (porous blocks), and 9920 (pavement bricks)

- Cycling speed: 35 seconds

- Pallet size: 850*550*30mm

- Power: 9.7kw

Depending on the fly ash brick making machine manufacturer you consult, some call this machine QT4-24 while others call it QT4-26.

If you’re in the market for a small machine that’s easy to operate and maintain, has high production capacity, and is durable, the LMT4-26 should be your best bet.

This semi-automatic fly ash brick making machine is the highest among the LMT series.

- Size: 3600*1730*2560mm

- Production capacity: 2240 (hollow blocks), 4480 (porous blocks), and 6720 (pavement bricks)

- Cycling speed: 20-26 seconds

- Pallet size: 850*450mm

- Power: 11.6kw

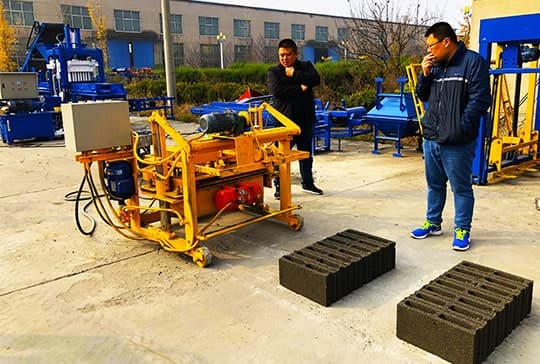

This semi-automatic fly ash brick making machine is mobile, small, and very affordable. Despite its affordability, it still boasts of a high production capacity, efficiency, and cycling speed.

It produces fly ash bricks directly to the concrete floor, hence, eliminating the need for pallets. The workers requirement is also really low which helps you cut spendings on labour.

In a bid to provide higher block density, the previous one time vibrations have been modified to two time vibrations.

- Size: 1600*1500*1200mm

- Production capacity: 2400- 4000 pieces/8 hours.

- Cycling speed: 45 seconds

- Pallet size: no pallet

- Power: 9.5kw

This is a semi-automatic fly ash brick making machine that uses high hydraulic pressure to produce fly ash bricks of high quality, density, and durability. Due to its reliance on hydraulic pressure and the strength of its frame, this machine is bound to last very long.

It is button-operated. You just need to push buttons to do many tasks. Hence, it is easy to operate and even maintain without necessarily having technical know-how.

- Size: 1300*1500*1000mm

- Production capacity: 400-4600 pieces/8 hours.

- Cycling speed: 23-25 seconds

- Pallet size: no Pallet

- Power: 6kw

QCM4-30 is a semi-automatic fly ash brick making machine, powered by a powerful diesel engine and electricity. The dual power option makes it a good fit for areas with epileptic power supply or no power at all. In addition, the diesel engine is fuel efficient.

The blocks produced by this machine have passed all tests by quality assurance organizations. They are durable, have high strength, and strong density.

To reduce the noise it makes, the whole machine (except the machine frame) hangs and connected parts are joined using springs. By using this special technique, a special damping effect is achieved.

- Size: 2050*1660*1900mm

- Production capacity: 2000-2500 pieces/8 hours

- Cycling speed: 30-40 seconds

- Pallet size: no pallet

- Power: 4kw or 6HP diesel engine

Lontto Semi Automatic Fly Ash Brick Making Machine Factory

Lontto supply semi automatic fly ash brick machine price, tech date, installation support. And Lontto is the top fly ash bricks machine manufacturer.

Lontto Semi Automatic Fly Ash Brick Machine

When you’re looking for fly ash brick making machines, lontto comes first due to several conditions.

For over 30 years, lontto has been producing fly ash brick making machines of reputable quality. Their machines are well-known for their efficiency and durability. Customers across the world can attest to this. In the time they’ve existed, Lontto has passed various certifications that verify its quality. We also employ over 1000 qualified professionals across several spheres.

Our journey with you starts from the moment you make an order but does not stop when you purchase. We have a dedicated customer service team available 24/7 and trained professionals available to help you with operation, installation and maintenance of our machines without charging you a cent.

So how do we ensure the quality of our machines?

First of all, all the workers are professionally trained. Hence, there are no errors in any aspect of the production process. Apart from that, we employ special techniques that ensure quality. The expertise of our workers has led to the development of over 30 patents.

Secondly, we source all our raw materials from reputable spare parts manufacturers across the world such as Siemens, Omron, Emerson, and many more. This does not only ensure quality, but makes repairs, maintenance, and operation of our machines a walk in the park.

Thirdly, we employ heat treatment for the frame of the machines and the moulds. Hence, they are both durable and long-lasting unlike several machines out there. There are many more.

We have several models of semi-automatic fly ash brick making machines. They include LMT$-40, LMT4-35, LMT4-26, QMJ4-45, QMY4-30, QCM4-30, and QMJ2-40. Making an order is very simple: visit our website, ask for a quotation to be sent to your email, then make a purchase. After you’ve made a purchase, we will deliver it to your country. Alternatively, you can pay a visit to our company in China. There is free accommodation already reserved for you.

Related Machines with Semi Automatic Fly Ash Brick Machines

Semi Automatic Fly Ash Brick Making Machine: The FAQ Guide

- What are semi-automatic fly ash brick making machines?

- What are the types of semi-automatic fly ash brick making machines?

- What are the prices of semi-automatic fly ash brick making machines?

- How can I buy a semi-automatic fly ash brick making machine?

- What are fly ash bricks?

- What are the advantages of fly ash bricks?

- How are fly ash bricks made?

What are semi-automatic fly ash brick making machines?

These are machines that are used to produce bricks, using fly ash as a raw material. It comes in different designs and sizes. There are some that run primarily on electricity while others depend on diesel.

What are the types of semi-automatic fly ash brick making machines?

Here at Lontto (your premium semi-automatic brick making machine manufacturer), there are two broad divisions:

- Semi-automatic fly ash brick making machine. Examples include LMT4-40, LMT4-35, and LMT4-26.

- Mini fly ash brick making machine. Examples include QMJ4-45, QMY4-30, QCM4-30, and QMJ2-40.

What are the prices of semi-automatic fly ash brick making machines?

Semi-automatic fly ash brick making machines differ in prices. The technical specifications, degree of automation, and other factors determine the price.

Before you go for any fly ash brick making machine, check the technical specifications and determine the price you are willing to spend on a machine. If you’ve settled these two considerations, you can then choose a machine.

If you need the prices, you could contact our customer service desk to send you the price quotations. You can then choose a machine that fits your price range and proceed to make an order. Our customer service desk will guide you along the process.

How can I buy a semi-automatic fly ash brick making machine?

A simple google search will reveal many options. However, you can buy from Lontto by making an order on our website or paying a direct visit to our factory.

What are fly ash bricks?

Before getting a hang of what fly ash bricks are, one must, first of all, understand its major component: fly ash.

Fly ash is the glassy looking residue formed after the combustion of pulverized coal in electrical power generation plants and thermal power stations powered by coal. They form when mineral impurities in the coal fuse together and flow out of the combustion chamber alongside exhaust gases. Formerly, it was often thrown away as waste but presently, using it is considered a huge benefit to the ecosystem instead of accumulating it at dumpsites. In recent times, fly ash has become a great additive to Portland cement. As a matter of fact, such cement has been discovered to develop great properties when fly ash is added. The properties include heat evolution, aggregate reaction, permeability, strength, easy workability, reduction in hydration temperature, etc.

Fly has a wide range of applications such as PCC, flowable fills, asphalt filler, concrete etc.

Fly ash serves as good additives to cement and water. They greatly improve the workability of concrete.

According to reports, 61 million tonnes of fly ash are generated each year. What this means, is that it is cheap and easy to obtain.

On the other hand, fly ash bricks are simply bricks in which fly ash has been used as an admixture. They have a strong correlation in colour, with concrete bricks.

The addition Of fly ash to concrete confers several beneficial properties which will be covered below.

What are the advantages of fly ash bricks?

Fly as bricks have several advantages both to the building itself and the environment in general. Some of them are:

- Fly ash bricks are far lighter than conventional clay bricks but still rank higher in strength per weight. Their weight makes them suitable for high rise buildings.

Although they are lighter, they still possess a high strength to weight ratio.

- Fly ash bricks help to rid the environment of the environmental pollutant (fly ash). Before the advent of fly ash bricks, steam and electric generation plants running on coal, had to dump fly ash in dumpsites. Hence, the environment suffered from it. Since a use for fly ash bricks has been found, this practice has been reduced greatly.

Another ecological gain of using fly ash, is associated with the soil. During production of clay bricks, a massive amount of soil is excavated. In recent years, many environmental conservationists have complained about the harm it causes to the environment.

- Money to be spent on mortar when using fly ash bricks is reduced. Even with the low amount of mortar consumed, fly ash bricks are still stronger than your regular clay bricks.

- Fly ash bricks have a very high compressive strength. As a result, fly ash bricks are less permeable. Hence, water does not seep through.

- Frost resistant. This is very important especially in areas that experience snow falls.

What are the advantages of fly ash bricks?

Fly ash bricks are made in three important steps: mixing, pressing and curing.

- Mixing

The raw materials – class C fly ash and sand – are fed into the materials hopper. After that, the conveyor belt moves the raw materials to the mixer where cement and water are then added. The raw materials are allowed to mix thoroughly for five minutes before moving to the next process.

It’s important to get the proportions and mixing time correctly as this will later determine the quality of the bricks.

- Pressing

The mixture is fed into the mould where high hydraulic pressure presses it into whatever design, shape or size taken by the mould. Vibrations are also used to shake the mould.

- Curing

The bricks are kept in the curing section for 15 to 18 days and watered twice daily to increase its density.